Machine tending is the most popular robot application and the Industrial robots are a great automation solution for this application. Before going too deep into details, let’s start with simple definitions.

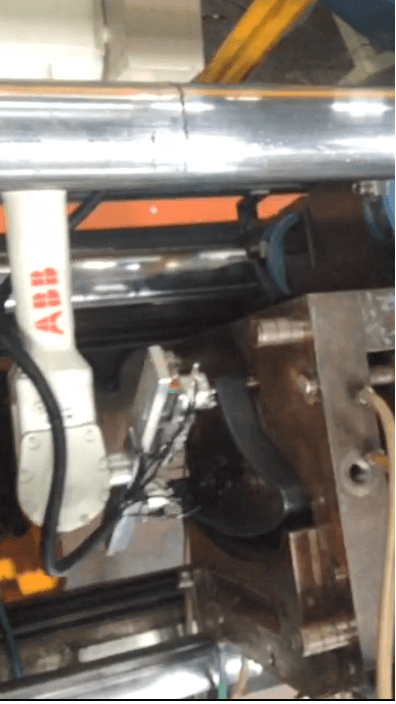

The basic definition of tending is providing treatment for someone or something. In our case, machine tending means to load and/or unload a given machine with parts or material. Currently, most machine-tending applications are done by humans. Modern machine shops often use CNC machines (such as lathes and milling machines). These machines must be tended by workers, who place the raw material (usually called the raw or blank part) in the machine and remove it once the machine has done its work. However, since qualified workers are becoming harder to find, companies are introducing robots into their workshops to make up for the lack of employees.

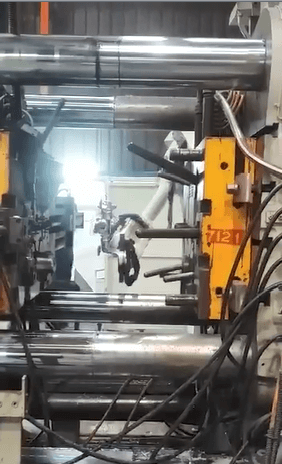

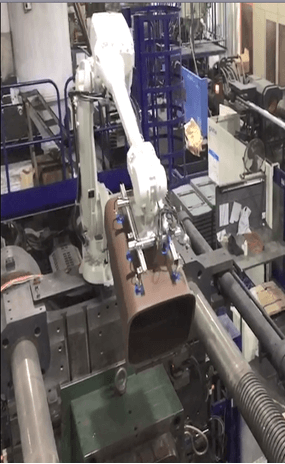

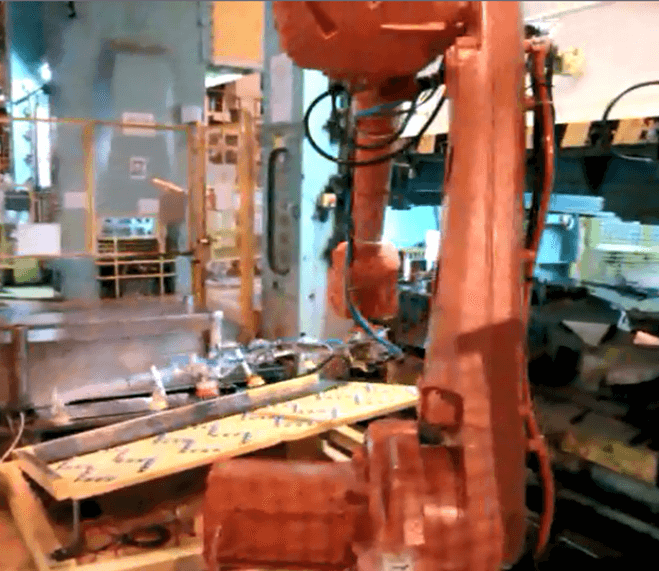

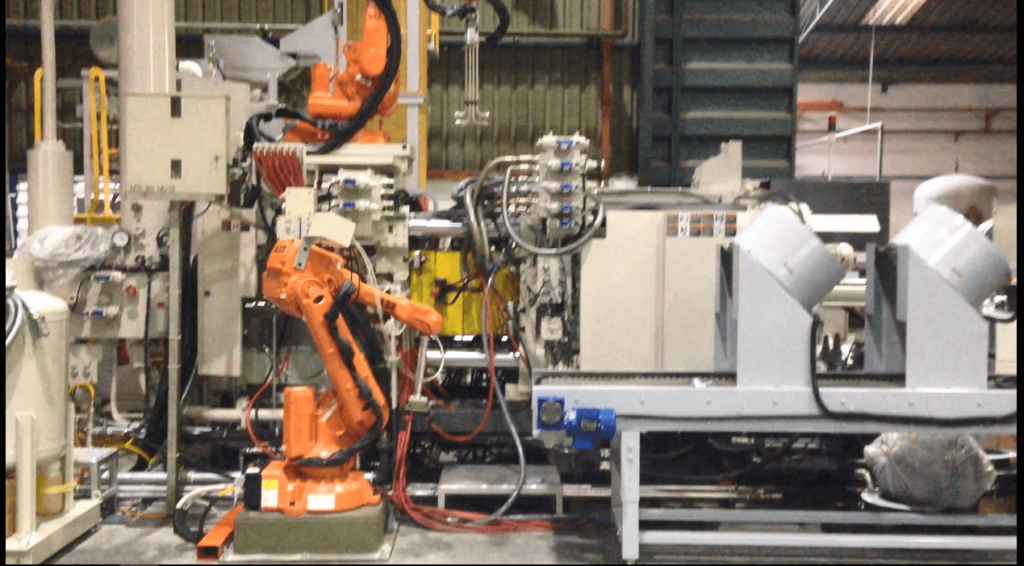

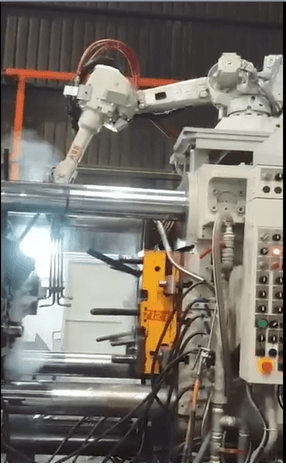

A robotic machine-tending process can be repeated endlessly, assuming the robot continually receives raw parts and the machine produces quality parts. Some industries use robots for a single step of production, like emptying injection-molding machines or CNC machines. When production is running around the clock, robots let you minimize cycle time and run the process continuously by removing parts from the machine’s working area.

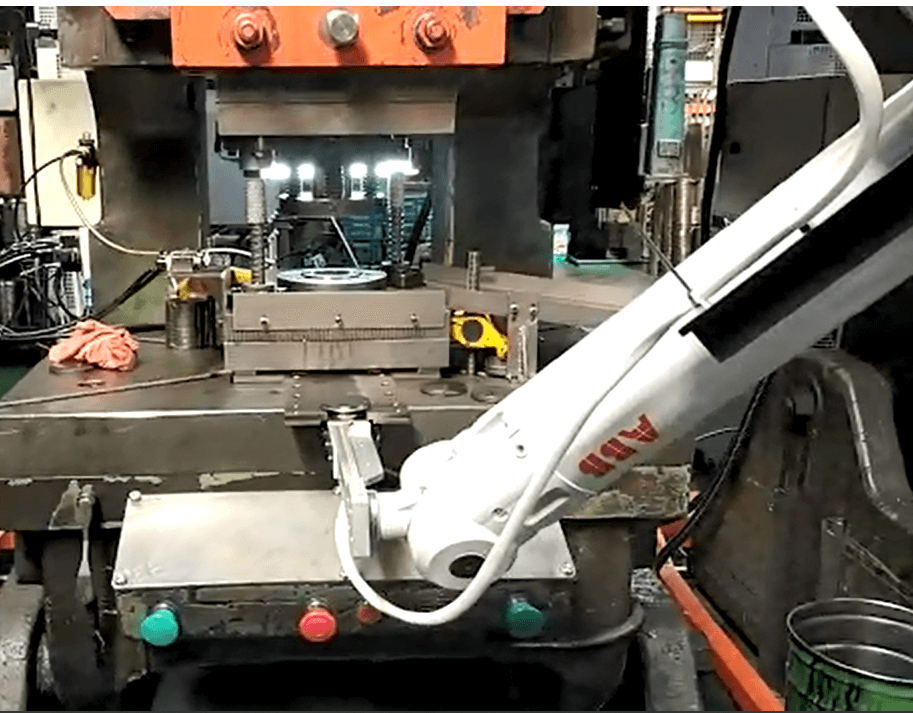

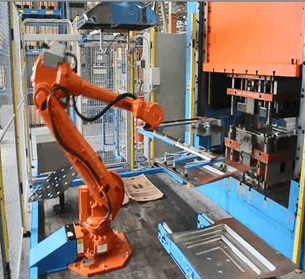

Using robots for machine tending decreases part cycle time, saving our customers money while ramping up productivity. Robots can tend all kinds of machines from presses and shears to injection molding machines.

Machine tending can be dull and dangerous work that requires a high level of consistency. Robotic machine tending keeps workers safe from the tedious, injury-inducing jobs, raising safety levels in facilities. The accuracy and reliability of our machine tending robot lines eclipse that of manual solutions.