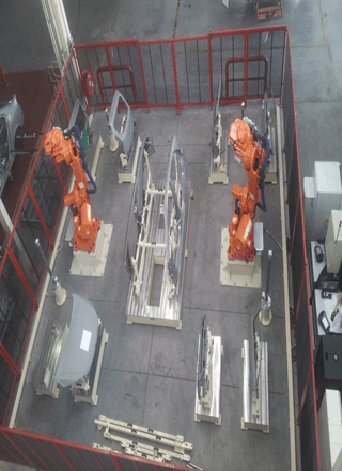

Industrial robots can be used to automate the tasks involved with putting together a product, there are used for lean industrial processes and have expanded production capabilities in the manufacturing world. An assembly line robot can dramatically increase production speed and consistency. They also save workers from tedious and dull assembly line jobs.

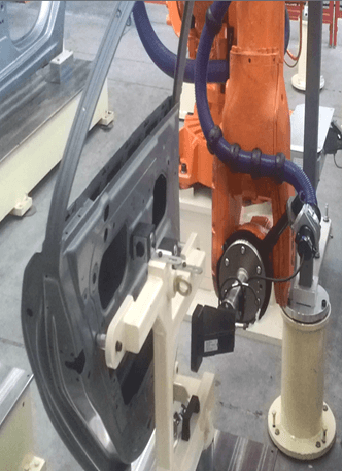

End of arm tooling can be customized for each assembly robot to cater to the manufacturing requirements. Additional options, like robotic vision, can also be incorporated to improve efficiency and accuracy of part orientation or sorting identifiers.

Robotics can automate some of the most tedious, dull, and unsafe tasks in a production line and is one of the easiest ways to add automation. Material handling robots enhance the efficiency of your production line and increase customer satisfaction by providing quality products in a timely manner.

The term material handling encompasses a wide variety of product movements on the shop floor. Part selection and transferring, packing, Pick and Place, Assembly and Inspection are just a few of the applications that are considered material handling.

When picking material handling equipment for your facility, you should consider payload and speed requirements, end-of-arm tooling or grippers needed, facility layout and floor-space, the type of material being handled and any additional possible production problems.

Robot vision components are often integrated into an assembly automation system to identify and sort parts, ensure proper placement and inspect the finished product.

Assembly applications typically consist of multiple operations. While the operations vary with the application, we’ve listed several of the most common operations below.

– Part Identification

– Part Sortation

– Flexible Feeding

– Bowl Feeding

– Bin Picking

– End-Effectors

– Tool Changing

– Force Sensing

– Part Fastening or Joining

– Visual Inspection