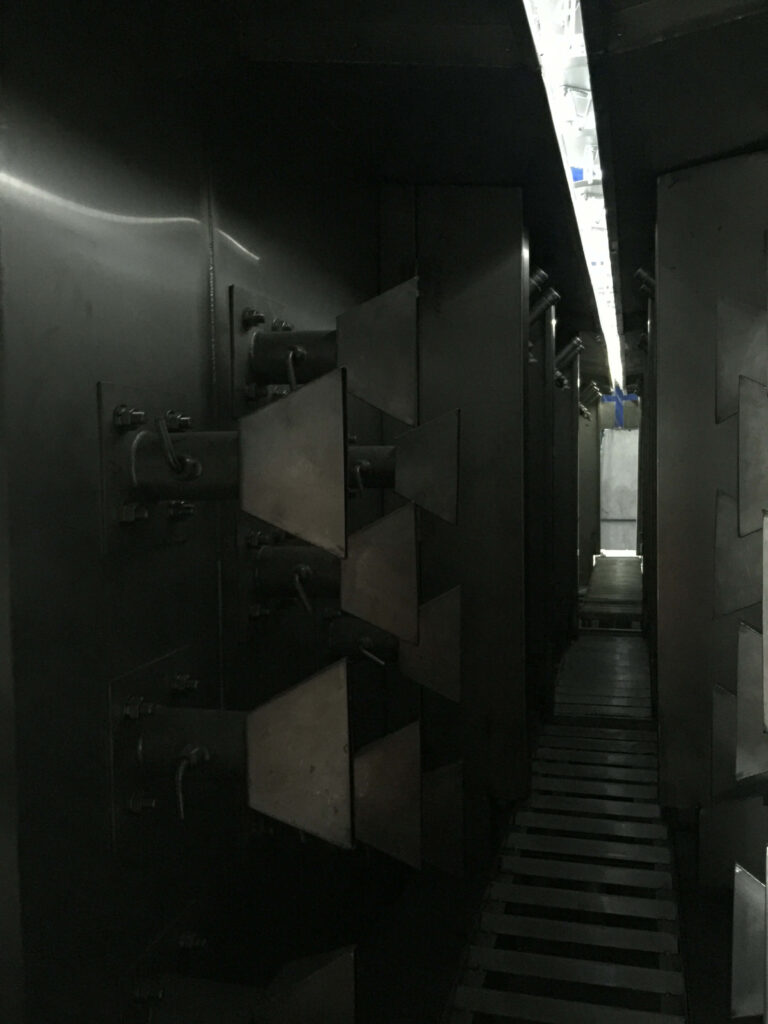

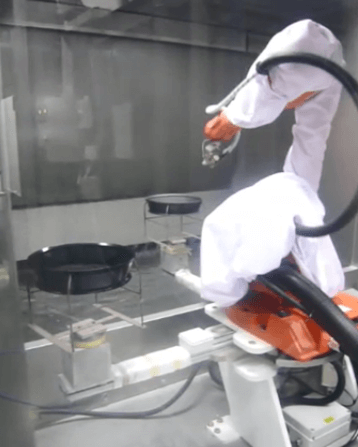

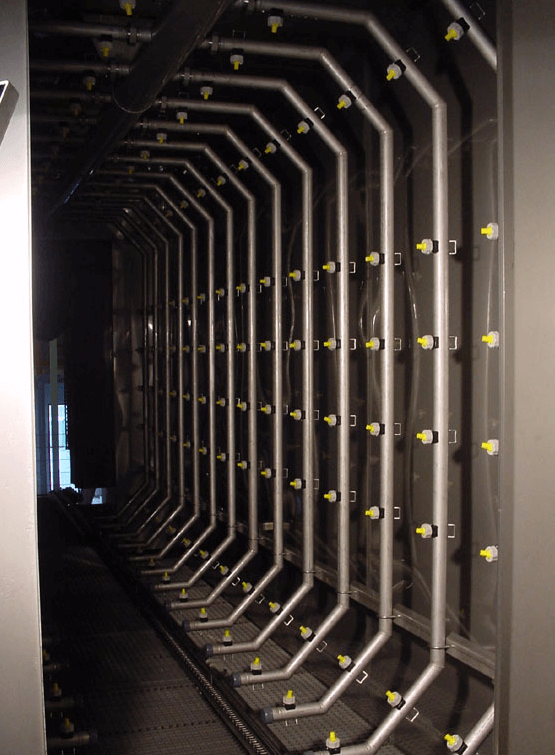

Automated painting applications require specialized equipment in order to achieve accurate and consistent paint finish quality. This specialized equipment includes an explosion-proof robot arm, spray applicator/bell, gear pumps, color change manifolds, solenoid valves, transducers and pressure regulators, to name a few. Paint robot provides a variety of technologies to solve the challenges associated with achieving consistently premium paint finish quality.

There are many companies that produce industrial spray painting arm that are sold to painting industries for use. For instance, company like FANUC, ABB, Yaskawa, Durr etc.

According the reports, the spray painting robots arm are useful in reducing hazard such as paint toxic, limiting material waste through consistent application and growing productivity. Other benefits of robotic spray painting arm is that it spray accurate, normal operation time is not long, it work for 24 hours uninterrupted with high reliability. It sprays paint with speed, it spray evenly and adjust the gun level and change automatically according to the work piece.

Robotic painting and coating provides a wide range of advantages, including:

– Improved safety in hazardous painting work environments

– Consistent paint application significantly reduces material waste

– Higher product speeds and productivity

– Increased system uptime